Table of Contents

Our Specialty Equipment

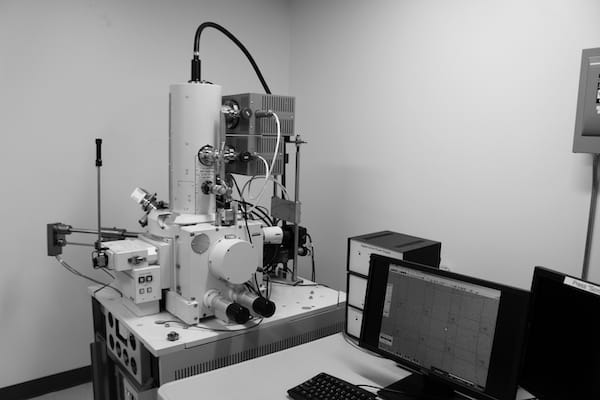

JEOL-6500f Scanning Electron Microscope

The JSM-6500f is a Field Emission Scanning Electron Microscope (FESEM) that contains an Electron Beam Lithography attachment. This allows for the 6500f to provide high-quality images of surface structures and inorganic structures. The Nanometer pattern Generation Systems allows for lithography applications with the ability to view structures down to 50 nm.

PM6 Precision Lapping & Polishing Machine

The PM6 is the latest addition of Logitech’s high-end lapping and polishing systems. With the ability to work with an assortment of materials including, Gallium Arsenide, Silicon, Rock, and Soils, the system's 100rpm allows for faster lapping rates. The dual abrasive feed and driven jig roller with a linear sweep allow for precision lapping and polishing on even the thickest wafers.

Quick Vision Apex 302 Pro

We are able to measure down to 1-micron features with our Quick Vision Apex 302 Pro, made by Mitutoyo. The Quick Vision Apex 302 Pro is a non-contact dimension measurement system that uses a CCD camera to take images, then uses image processing technology to determine the edges of the workpiece. Due to the non-contact ability, there is no risk of workpiece damage.

AJA Sputter, ATC 2400 Sputtering System

The AJA Sputter Gun, ATC 2400 contains five shuttered magnetron guns to deposit single film layers over 4”-6” wafers. The DC gun that is equipped deposits conductive material while the four RF guns deposit semi-conductive or non-conductive material. The RF substrate biasing allows for plasma substrate cleaning or ion-assisted reactive sputter deposition.

GEMStar XT-S/D™ Benchtop Thermal Atomic Layer Deposition

The GEMStar XT-S/D™ is one of the industry's top benchtop Atomic Layer Deposition (ALD) Systems. The system offers up to 450 ℃ ALD processing through the full range of substrates. With a Pulsed Vapor Push(PVP™) and a selectable flow-through and exposure modes of deposition, the GEMSTAR XT-S/D™ has the ability to handle low-pressure material. Whether it is working with biotechnology, solar cells, or energy, this customizable system allows for high-quality films and Atomic Layer Deposition.

STS Pegasus DRIE Etcher

To create deep anisotropic etching of silicon, the Bosch Process on our STS Pegasus DRIE Etcher switches between different plasma chemistries to provide fluorine based etching of the silicon while protecting the sidewall of the growing feature with a fluorocarbon layer. It is a complex but flexible plasma process with key process variables including gas flows, RF power, platen power, and switching times.

EVG®6200 NT Aligner

The EVG6200 NT provides state-of-the-art mask alignment technology with advanced alignment features. The EVG6200 NT mask alignment system is equipped with integrated vibration isolation to achieve excellent exposure results for a wide range of applications, such as exposure of thin and thick resists, patterning of deep cavities, and comparable topographies, as well as the processing of thin and fragile materials such as compound semiconductors.

Features

- Wafer/substrate size from pieces up to 200 mm/8’’

- Supports versatility of lithography processes

- Throughput up to 180 WPH in first print mode or up to 140 WPH in automatic alignment mode

- Fragile, thin or warped wafer handling of multiple wafer sizes with quick change-over time

- Automated contact-free wedge compensation sequence with proximity spacers

- Auto origin function for precise centering of the alignment key

- Dynamic alignment function featuring real-time offset correction

- Supports the latest UV-LED technology

- Manual substrate loading capability on an automated system

- Multi-user concept (unlimited number of user accounts and recipes, assignable access rights, different user interface languages)

CNC Center: Mycenter-HX250iG

The Mycenter-HX250iG is our state of the art CNC Center. This CNC enables drastically reduced set-up times and has a positional accuracy of 1.905 microns. Full Stroke and a Repeatability of 0.99 microns. Along with an ultra-high feed rate of 2,362ipm and high-speed processing Arumatik-Mi CNC with 67 million pulse coder technology, the Mycenter-HX250iG is suited for a wide range of capabilities.

Automated Plating Station

Custom robotically controlled cassette to cassette plating station. Enables 24 hour processing.